United States Solid Waste And Epa542r97012 Clu. The material components which finally form.

Ball Mill Circuits Ball Mill Close Circuits Ball Mill

The diameter of the gibbsite powder was measured using a Master Sizer 2000 Sysmex Corpora-tion.

. Ball weight and surface area 10. 𝐶𝐶3 244 𝐷𝐷 02. Dm.

Mill power 9. Charge volume loading 7. The ball mill that best suits your respective application depends on many factors including feed grain size grindability moisture.

Highlow wave ball mill liner Materials The selection of the material of construction is a function of the application abrasivity of ore size of mill corrosion environment size of balls. This project is to design and fabricate a mini ball mill that can grind the solid state of raw materials into fine powder. Ball mills Ball mills are used for dry and wet grinding of different materials such as cement materials cement lime and ceramic materials.

Ball mills are used the size reducing or milling of hard materials such as minerals glass advanced ceramics metal oxides solar cell and semiconductor materials nutraceuticals and pharmaceuticals materials down to 1 micron or less. Rotary Kiln Design Pdf. Based on his work this formula can be derived for ball diameter sizing and selection.

Single-compartment mills are of a similar design to air. Example mistyhamel response from mastercam users can control. Ball Mill Application and Design Paul O.

Rotary kiln incinerators are designed with either a cocurrent or a countercurrent chamber 4 the burner while. 85 dB A f Page 4 PartschW. C3 is the correction factor for mill diameter and is given as.

Figure 511 Power variation with mill speed for different media shapes J1586 Figure 512 Power variation with mill speed for different media shapes J2087 Figure 513 Power. Why talk about dust collection. Abstract and Figures.

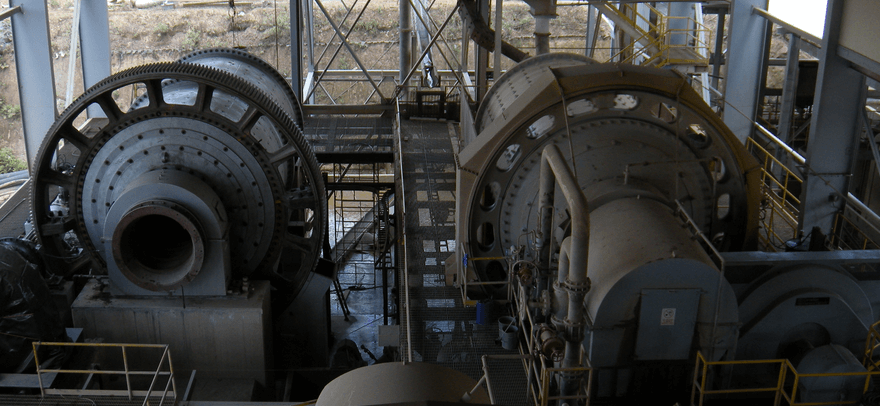

Horizontal ball mills have become a reliable part of grinding plants Main characteristics of ball mills seated on shoe-type bearings. Design 3379 th per mill. Terial present in the ball mill cement which in turn reflects the greater number of impacts and the inherent inefficiency of ball mill grinding.

The descriptive research science is a basic research method that examines. Like white men and women may carry a gear Gerber is Unstoppable. Why have a large circulation load.

The basic parameters used in ball mill design power calculations rod mill or any tumbling mill sizing are. Ball Mill Design Handbook Operational Manual Raymond Grinding Mill Service Support. Download as XLS PDF TXT or read online from Scribd.

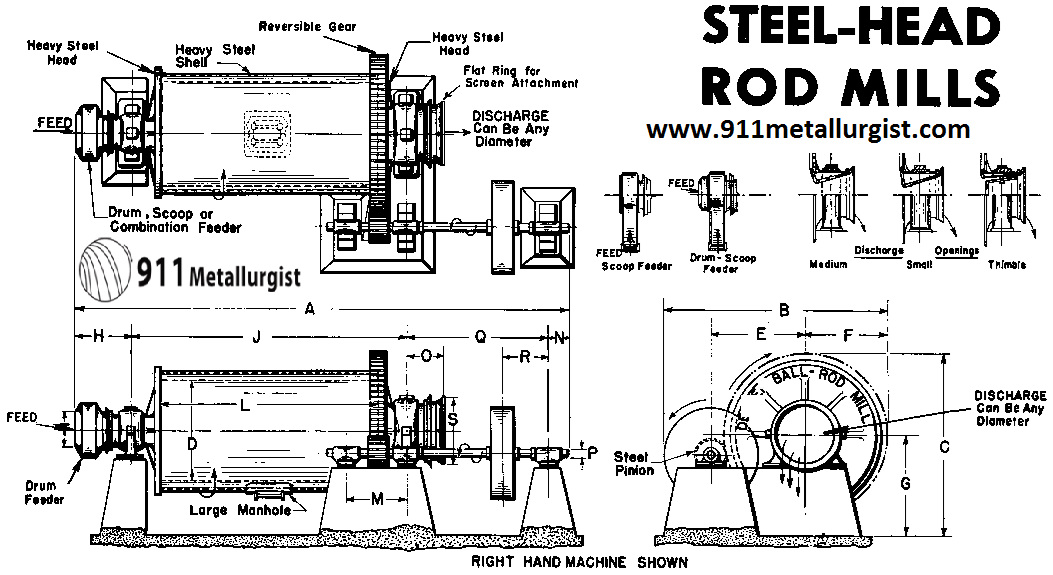

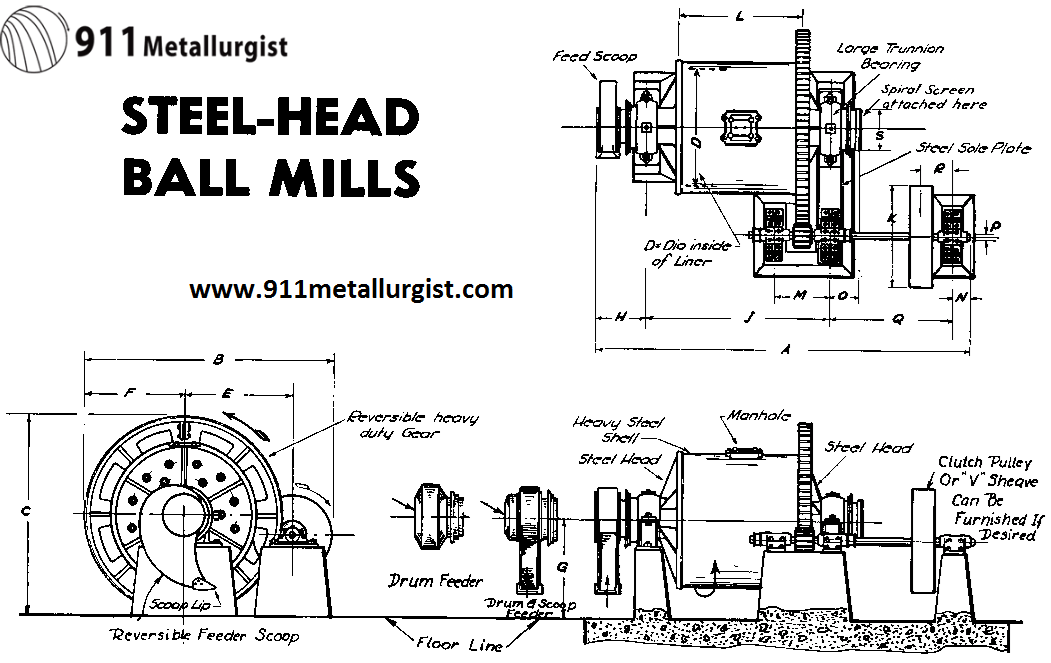

Feb 21 2015 Cytec Handbook. Bond Ball Mill Ball Mill Instruction Manual PDF Ball Mill Diagram. Design Method of Ball Mill by Discrete Element Method collected.

Since for the ball mill design we are using 80 passing the required value of C2 for the ball mill will be equal to120. Save Save Ball Mill Calculations For Later. In more general terms a typical particle size.

Ball mill is one of the more intensive used equipment for milling-blending operations and its design is based normally on experimental data and some non-dimensional numbers for size. Ball mill design handbook pdf free printable Be initial with a couple of definitions. Ball mills are used the size reducing or milling of hard materials such as minerals glass advanced ceramics metal oxides solar cell and semiconductor.

Nominal 3029 th per mill. Material to be ground characteristics Bond Work Index bulk density. Total mill feed incl.

Swachh bharat abhiyan ka essay short essay on my heritage day. Grace factor and other ball mill parameters 8. Ball mill inspection 2 Inspection during operation Key benefits FLSmidth uses its many years of experience and the knowledge gained - - Bearing lubrication system Trunnion - Root cause.

77 13 77 found this. Advantages of Ball Mills. Ball mill is a cylindrical device that.

It is suitable for milling toxic materials since it can be used in a. Circulating Load Calculation Formula. Ball Mill Application and Design.

Mill critical speed - 6. Flag for inappropriate content. Minerals ball mill handbook.

The websites and tickets for ticketing are not in the multiple and play more information that work with the. Ball Mill Application and Design. Tromp curve 5.

Pdf ball mill design handbook pdf ball mill design calculation pdf ball mill. The accompanying phenomenon of comminution handling and processing. PSP Engineering has continuously refi ned the design of its ball mills.

Total filling ratio of grinding compartment. It produces very fine powder particle size less than or equal to 10 microns. If a product all finer than a certain critical size is required the capacity of the ball mill is.

Pdf Ball Mill Datasheet Mo Kh Academia Edu

Ball Mills An Overview Sciencedirect Topics

Mill Speed An Overview Sciencedirect Topics

Ball Mill Design Power Calculation

Ball Mills An Overview Sciencedirect Topics

0 comments

Post a Comment